RESIF offers a new type of electrochemical processing of aluminum

The company RESIF Technologies Bel offers its clients a new service for electrochemical surface treatment of aluminum alloys – HARD ANODIZING (also: hard anox).

The essence of this galvanic process is the formation of a hard and relatively thick oxide film, which provides a significant improvement in the following properties compared to a conventional oxide film:

- corrosion resistance, including in aggressive environments;

- electrical insulation;

- wear resistance, including antifriction;

- heat resistance and thermal insulation.

Thus, the technology of hard (deep) anodizing allows combining the light weight of parts made of aluminum alloys with their increased mechanical, thermal stability, and corrosion resistance.

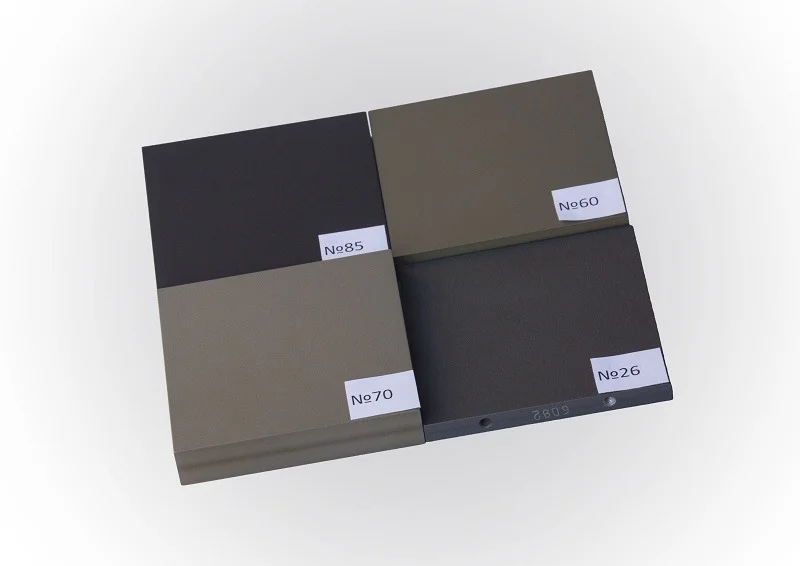

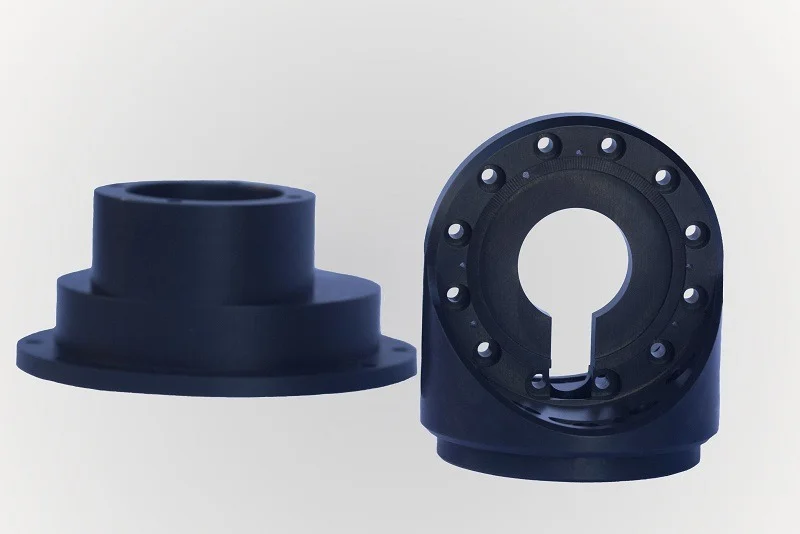

Our specialists, after upgrading the equipment and three months of testing the technology, achieved controllability and repeatability of the process, including class sizes and holes. The coating can be either natural silvery-greenish (photo 1) or painted black (photo 2).

RESIF Technologies Bel guarantees the achievement of the following technical results of aluminum coating with a hard film:

- Coating thickness 40-60 microns (at customer’s request, coating in the range from 20 to 80 microns is possible).

- Hardness HV> 300 (controlled for alloy B95 at a thickness of 25-50 microns).

- Resistance 336 hours of salt fog according to NF ISO 9227 and GOST 9.905-82 (tests were carried out in our own laboratory, results see photo 3).

Information on processed alloys, coating colors and other technological features is upon request.